LANXESS offers new polyamides and polyesters for laser transmission welding by Focusing on the components for electrified and autonomously driving automobiles: High transparency in the near infrared wavelength range; Flame-retardant, tough, and corrosion-resistant product variants; New hydrolysis-stabilized PBT compounds under development.

LANXESS offers new polyamides and polyesters for laser transmission welding by Focusing on the components for electrified and autonomously driving automobiles: High transparency in the near infrared wavelength range; Flame-retardant, tough, and corrosion-resistant product variants; New hydrolysis-stabilized PBT compounds under development.

Can be automated, is gentle, flexible, and lint-free

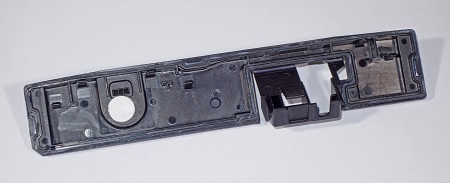

In the procedure, a laser beam is sent through a laser-transparent component and absorbed by a second, often black-pigmented component below. This generates heat that melts the surface of the second component. The surface of the first component also melts through heat conduction, so that a material-joining in the form of a weld is created between the two components. The process has several advantages: Thus, it is easy to automate and, compared to vibration, ultrasonic, and infrared welding it is thermally and mechanically less stressing. It allows the joining of 3D contours and hard/soft material combinations. Depending on the size of the component, the cycle times are considerably less than 30 seconds, and the welding flash is – if at all – extremely low. In addition, welding seams are created without lint. This means, for example, that welded liquid containers do not have to be washed out for cleaning after production.

Flame-retardant and easy to process

One highlight among the new compounds from LANXESS is the halogen-free flame-retardant Durethan AKV30FN04LT. The light transmission for this polyamide 66 is comparatively high in the wavelength range usual for laser welding at wall thicknesses of up to 1.5 millimeters. “The heat input at the boundary layer is thus fast, so that the joining area also melts quickly, which makes economical production possible,” says Krause. The compound shows a very high tracking resistance and achieves the best classification of V-0 (0.4 millimeters) in flammability testing pursuant to the United States’ UL 94 (Underwriter Laboratories Inc.) standard. Its flame-retardant package is optimized with regard to its thermal stability. Injection molding therefore involves a considerably lower risk of deposits forming on the mold surface. The compound contains a heat stabilization system that does without metals and halides. As a result, it has a low tendency to contact corrosion when in contact with conductive parts. This is important, for example, for components in high-voltage batteries or for safety switches.

Tough and low shrinkage

Three other new polyamides have also been optimized for a low tendency to electrocorrosion. Durethan AKV25H3.0LT is particularly suitable as a material for components with high short-term thermal loads. The polyamide 66 is glass fiber reinforced and thermostabilized with a metal- and halogenide-free heat stabilizer. Durethan B31SKH3.0LT, on the other hand, is an unreinforced polyamide 6 and is predestined for components with high toughness requirements. Durethan BG30XH3.0LT is ideal for components that need to be particularly low in distortion and shrinkage – such as filigree electronics housings or connector strips. The polyamide 6 is reinforced with a mixture of glass fibers and microglass beads.

Good laser transparency even with thicker walls

Please read more from the: “SOURCE”

************************

Why Should Be “A Paid-Subscriber” and “Advertiser”

Keeping an independent media in countries that impose limitations on self supporting media, will help to support the humankind’s freedom. If you believe it, please act to be a PRO-MEMBER by clicking “HERE“, or:

Please send your PR’s directly to my email address to be published in the world via ” http://pimi.ir ” my address is: aasaatnia@live.com