The quality of foam components owes a lot to optimal sealing and degassing in the foaming tool. Particularly for the manufacture of complex interior parts such as instrument panels or door trims, this is a key issue. With PURe Seal, Frimo offers a sealing system for polyurethane foaming tools, which provides both technical advantages and economic benefits. For two years now, Frimo has been working with PURe Seal end pieces. Before serial production, a comprehensive test phase was conducted during which customers were able to test the end pieces thoroughly. In addition to BMW as OEM, users also include Tier 1 suppliers such as Faurecia, Grupo Antolin, SMP, and Yanfeng.

According to Frimo, in order to meet the automotive industry’s strict quality requirements, the choice of the right sealing system is a key factor for the foaming process. Inserting the fluid PU triggers a chemical reaction in the closed mould during which gas is released. If this is unable to escape, gas bubbles form in the material. These so-called shrink holes must be avoided due to their negative impact on component quality. Unintentional and uncontrolled leakage of the foam system during this process must also be prevented. In order to let the gas escape during the foaming process in a controlled manner, seals are integrated into the foaming tool. For this, the sealing is carried out circumferentially around the foaming areas. The choice of the right sealing system is therefore crucial for optimally filling the cavity, and also decisive for optimal foam homogeneity.

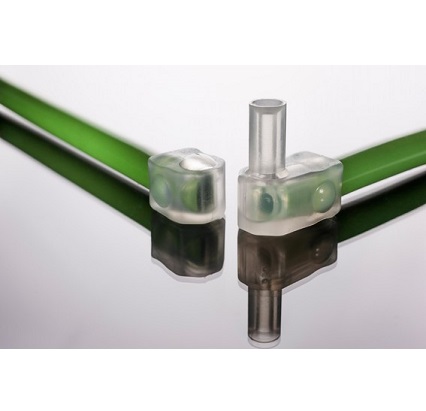

There are a variety of different sealing systems on the market in order to meet the multiple customer demands as well as specific requirements depending on component and project parameters. For many years, Frimo has offered a pneumatically inflatable sealing system, which enables a compensation of potential tolerances in the components undergoing the foaming process. For a long time, a patented carding end piece was used which placed stricter requirements on handling. In order to design handling optimally and comfortably for customers, the new flexible PURe Seal end piece, inflatable over its entire length, was developed and introduced onto the market after comprehensive series of tests were performed by various customers. All PURe Seal sealing components are made of silicone, which in itself ensures lower foam adhesion. The pressurised air is inserted here through the tool seating, as was the case for the conventional end piece. Using a sealing lip, the end piece seals itself inside the core drill hole during this process. An additional sealing lip ensures a seal between the hose and … .

Read More From The Source