Agr International will feature its latest advancements in polyethylene terephthalate (PET) bottle production management and quality control at Pack Expo 2016.

Products featured at this year’s event will include the following:

Process Pilot – The Process Pilot automated blowmolder management system is designed to help PET bottle manufacturers measure, control and optimize their bottle blowing process. The system interfaces with the blowmolder to provide precise material thickness distribution on a per bottle basis, while managing the blowmolder to eliminate the effect of process and environmental variables that impact bottle material distribution throughout the production cycle.

CrystalView – The latest enhancement to the Process Pilot product line is the CrystalView material optimization system. The CrystalView system provides PET bottle manufacturers with the means for automatic management of material orientation/crystallinity. The system works in conjunction with the Agr Process Pilot blowmolder management system to simultaneously manage material distribution and optimize material orientation. By doing so, material orientation is optimized over the entire bottle, making it possible to produce the best possible bottles, at the coldest practical processing temperature.

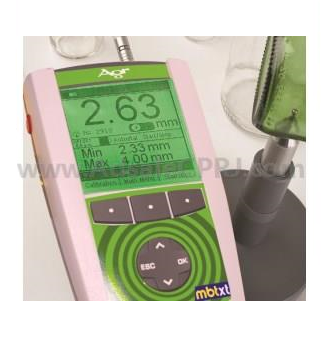

MBTxt portable thickness gauging system – Agr International will unveil its latest version of the MBT measurement system. This compact device is capable of achieving extremely precise thickness measurements boasting a low range resolution of 0.1μm. The MBTxt offers a number of advanced features including a greatly extended measurement range up to 25mm. The MBTxt is ideal for the intricate requirements of container measurement. However, its applications are not limited to containers, as the MBTxt can be used to measure all types of non-ferrous materials up to 25mm thick.

Source : China Plastic & Rubber Juornal