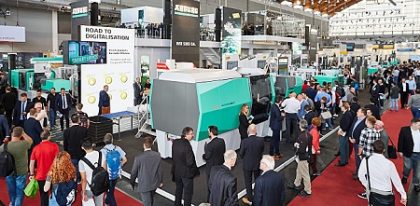

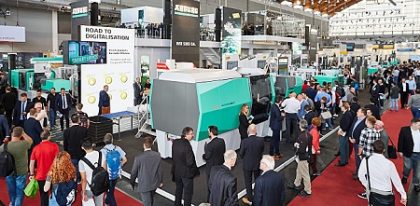

From 16 to 20 October 2018, ARBURG provided an overview of the future of injection moulding at the international Fakuma trade fair in Friedrichshafen, Germany. The main focus was on the “Road to Digitalisation”.

From 16 to 20 October 2018, ARBURG provided an overview of the future of injection moulding at the international Fakuma trade fair in Friedrichshafen, Germany. The main focus was on the “Road to Digitalisation”.

Digitalisation and new colour scheme

Everything came together for us at the Fakuma 2018: ambitious technology in an ambitious design with an ambitious exhibition stand,” says Michael Hehl, ARBURG Managing Partner and Spokesperson for the Management Team. The main focus was on the “Road to Digitalisation” and the new, modern mint green, light grey and dark grey colour scheme in which all the ALLROUNDERs appeared for the first time. The unanimously positive feedback from the visitors demonstrated that ARBURG has struck the nerve of the times with its “Road to Digitalisation”. At various stations, experts provided information on the digital assistance packages and offered an insight into the future, e.g. the GESTICA control system with filling simulation, augmented reality (AR) for “smart” service and the introduction of the new customer portal.

Innovative products, processes and applications

Further highlights included the premiere of the ALLROUNDER 820 H in the “Packaging” version and the new clamp design, a turnkey system featuring the new SCADA system ARBURG Turnkey Control Module (ATCM) and automated micro LSR injection moulding. Further innovative applications with the ALLROUNDERs and the freeformer at the ARBURG and partner stands as well as a dedicated recruiting stand rounded off the company’s presence at the Fakuma.

In the same regard, it is not too much out of the readers’ focal point, when a very active American news daily writes:

“Arburg GmbH & Co. KG is no stranger when it comes to recruiting and training the next generation of workers.

In September, 67 new students from Germany’s Baden-Wuerttemberg Cooperative State University started their vocational training at the injection molding machinery maker.

Arburg said it was the largest cohort yet to start apprenticeships at the Lossburg, Germany-based company, with students filling positions such as mechanical, electrical and industrial engineers, mechatronics technicians, technical product designers and industrial clerks.

Earlier this year, Arburg’s apprenticeship department received three quality certifications: an LQW certificate, a 1A Excellent Training Company seal of quality from the Northern Black Forest region’s Chamber of Commerce and Industry, and an ISO certificate for meeting the basic requirements as a provider of learning services in nonformal education and training.

“Arburg is regarded as an attractive employer and an excellent education company in the region,” said Renate Keinath, a managing partner at Arburg who is also responsible for human resource management.

Please reade more from PN Daily Report (Click Here)

************************

Why Should Be “A Paid-Subscriber” and “Advertiser”

Keeping an independent media in countries that impose limitations on self supporting media, will help to support the humankind’s freedom. If you believe it, please act to be a PRO-MEMBER by clicking “HERE“, or:

Please send your PR’s directly to my email address to be published in the world via ” http://pimi.ir ” my address is: aasaatnia@live.com