Today Thursday Ai 9th., The Saudi Arabian Company – SABIC– launched a non-chlorinated and non-brominated opaque sheet, LEXAN™ CLINIWALL™ AC6200. The sheet aims to provide a hygienic, sanitary solution for interior surfaces to several industries around the world.

The launch comes as the rising need for infection prevention and sanitation control across the world continues to increase. SABIC’s full integration across the value chain allows the company to develop robust solutions that help meet customers’ needs.

Typical industries for the solution include hospitals, clinics, homes for the elderly, primary care centers, sterile rooms, laboratories, pharmaceutical factories, industrial kitchens, storage rooms and refrigeration facilities, schools, restrooms, airports, bus stops, train stations and sports centers.

“As customer needs and demands continue to evolve, we are helping to solve some of the biggest challenges the world faces today. It is important now more than ever for public, industrial and healthcare facilities to be equipped with products that include anti-bacterial properties to ensure the safety of their staff, patients, customers and anyone who may walk through their doors,” says Peter van den Bleek, Product Manager for SABIC.

When independently tested over a 24-hour period at 35 degrees Celsius, LEXAN™ CLINIWALL™ AC6200 Sheet with anti-bacterial shield showed greater than 99.99% reduction in Methicillin- Resistant Staphylococcus Aureus (MRSA) and 99.999% reduction in E. Coli on the surface of the material.

“The anti-bacterial material provides a layer of protection to interior wall cladding against the spread and multiplication of potential bacteria (MRSA and E. Coli). This makes it an excellent choice for patient care and other hygiene-sensitive clinical operations,” says Peter.

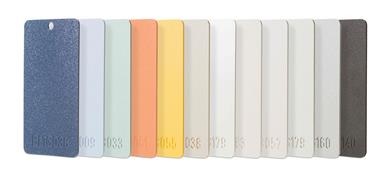

LEXAN™ CLINIWALL™ AC6200 Sheet is also a non-chlorinated, non-brominated, halogen free and fire-resistant opaque material, which delivers high impact and wear resistance. The sheet further offers excellent stain, blood and urine resistance, as well as chemical resistance to popular cleaning agents like disinfectant Isopropanol (rubbing alcohol), helping to save significantly on maintenance costs.

Tha last article about “SABIC” published at Polymer Industry Media International was: SABIC Launched Advanced Filament Aiming To Improve Parts Manufacturing Productivity