3Percent increase in import of PP in 2016

According to PIMI Russian correspondent (Olga Prodovskaya): At the beginning of 2016 import of Polypropylene to Russia has grown by 3%. Her reports says:

Following the results of the first two months of the current year the total volume of import of Polypropylene (PP) to Russia has grown by 3% in comparison with a similar indicator of 2015 and has made a little more than 22,4 thousand tons. The main gain of deliveries has had on Homopolymers of Propylene whereas the Russian producers managed to reduce external supply of Polypropylene Random Copolymers (PPR).

The local companies have reduced volumes of purchases molding Homopolymers of Propylene in Europe. Following the results of January – February of the current year the total volume of import of this type of PP has grown to 9,9 thousand tons against 8,4 thousand tons the previous year.

For the considered period external supply of block Copolymers of Propylene to Russia has grown to 4,9 thousand tons that is 6% more in comparison with a similar indicator of 2015. The main gain was provided by local producers of pipes.

Import of polypropylene random Copolymers following the results of the first two months of the current year was reduced by 15% – to 3,9 thousand tons. Dependence of the Russian producers in sector of BOPP-films is still strong from external deliveries whereas purchases PPR for production of pipes by the Russian producers have been almost brought to naught (due to growth of own production).

External supply of other polymers of Propylene for the considered period has made 3,7 thousand tons against 4,1 thousand tons the previous year.

********************************************************

News Edited and Wired By:

PIMI Russian News Correspondent

Olga Prodovskaya

Journalist, former Editor-in-chief of Plastics Magazine, Russia

***********************************************************

About Copolymers:

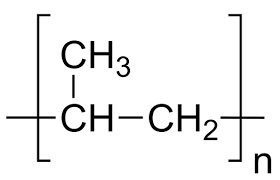

When two or more different monomers unite together to polymerize, their result is called a copolymer and its process is called copolymerization.

Commercially relevant copolymers include acrylonitrile butadiene styrene (ABS), styrene/butadiene co-polymer (SBR), nitrile rubber, styrene-acrylonitrile, styrene-isoprene-styrene (SIS) and ethylene-vinyl acetate.