ITIB Corrugator Towards Turkey via K 2016: The test of another extrusion line for the production of large diameter PE double wall corrugated pipes for storm and sewage water drainage has been successfully completed at ITIB MACHINERY’s factory, in Paderno Franciacorta, Italy.

The fast growing diffusion in the market of this product, as a valid alternative to the common concrete or PVC pipes, has led the Company to strong investments to promote and manufacture this type of equipment. The F700SH9 corrugator, the heart of this extrusion line, actually represents the largest machine in ITIB Machinery’s range of products. It is able to produce pipes with an outer diameter starting form 200mm up to 700mm. The wide range allows to cover production of pipes up to 630mm, in case of standard according the outer diameter or 600mm, in case of inner diameter.

The corrugator is complete of all the most updated technical solutions like: open shuttle construction, integral cooling, with chilled water flowing directly inside the moulds, vacuum forming system and is characterized by the interesting, uncommon and extremely useful possibility to open the moulds forming channel, in case of any emergency stop or power failure. This solution allows an easy access to dies and cooling mandrel of the inner layer and consequently, a quick removal of any plastic material and fast new start up of the line. In case of power failure, a UPS unit, supplied with the line, allows the main movements of the equipment. The geometry of the pipe profiles has been studied to fulfil the standard EN13476 and to get a very low pipe weight.

The line that has been tested is allocated to an important Turkish producer. The customer will use injected couplings with double sealing rubber ring to join the pipes. The pipes that have been produced present a uniform and constant material wall thickness, guaranteeing a high quality bell and joint. The same pipes can be joint with any alternative solution such as over injection of the coupling, spin welding or welding with added plastic material.

The line was completed by a stainless steel cooling tank, produced by ITIB Machinery, extruders, planetary cutting unit and tilting unit. As far as the productivity of the line is concerned, outputs from 500Kg/h up to 700Kg/h, depending on the pipe size, have been reached.

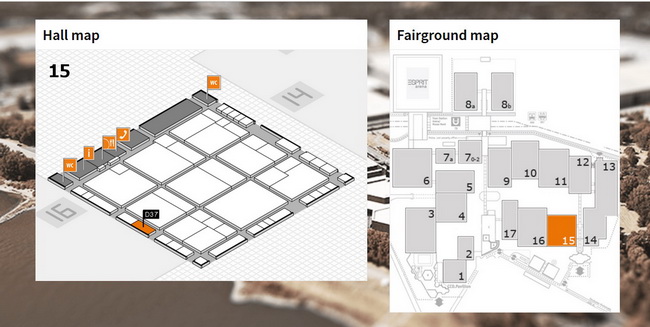

The ITIB Technology and machines will be at the K 2016 visitors’ disposal from Oct. 19-26, 2016 in Dusseldorf at Hall 15 stand D37