Manufacturers are the innovators of future technology, and many times they choose to commercialize their innovations on the open market. That’s what Littlestar Plastics (Machesney Park, IL), a custom injection molder with 25 years of experience in engineering and producing high-tolerance plastic components, has done with its IndiCert.

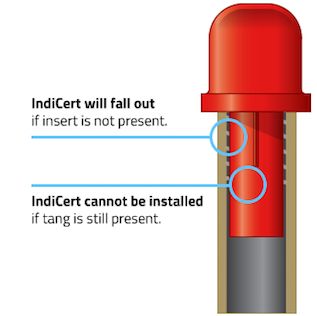

Littlestar created IndiCert to quickly identify whether threaded inserts are installed correctly. Threaded inserts are fasteners that are used to insert long-lasting threads in plastic, metal or composite materials. Before an assembly containing threaded inserts is completed, the assembler twists the IndiCert into the insert. If the driving tang is still in place or the threaded insert is improperly installed or not installed at all, then the IndiCert will not seat.

Company founder and President Phil Preston said that until now there has been no way to quickly identify whether all the threaded inserts have been installed correctly. When even one is missed, it can cause a shipment to be rejected, which is bad for the company doing the assembly but even worse for those facing delays farther up the supply chain.

“A lot of the companies we work with are on very tight schedules and if they miss testing dates it can cost them millions,” said Preston, adding that “the brightly colored IndiCert will make it easy to verify at a glance whether or not there is a problem. You know you have an issue if you have … .