The following article is re-published from a PR, however and based on PIMI policy it has been more completed by addition of links and images.

***********************************************************

Cyanobacteria have shown promise to produce citramalate, a key component for making sustainable plastics like Perspex.

The University of Manchester team says that these photosynthetic microorganisms showcase the ability to transform CO2, a major greenhouse gas, into useful materials.

23-fold increase in citramalate production

Cyanobacteria, also known as blue-green algae, are tiny organisms that use sunlight to convert CO2 into organic  matter. Notably, they offer a sustainable alternative to traditional methods by producing valuable products from CO2. They do so without the need for agricultural resources like sugar or corn.

matter. Notably, they offer a sustainable alternative to traditional methods by producing valuable products from CO2. They do so without the need for agricultural resources like sugar or corn.

“Our research addresses one of the key bottlenecks in using cyanobacteria for sustainable manufacturing,” said Matthew Faulkner, the lead researcher.

“By optimising how these organisms convert carbon into useful products, we’ve taken an important step toward making this technology commercially viable,” Faulkner added.

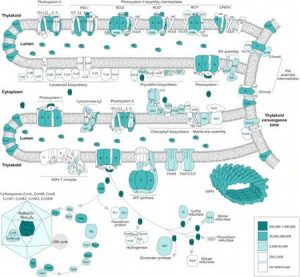

The research focused on Synechocystis sp. PCC 6803, a common cyanobacterial strain. They genetically modified the train to facilitate conversion of carbon dioxide to bio-based materials.

This research aimed to enhance the production of citramalate.

Citramalate is produced in a single enzymatic step by combining two metabolites: pyruvate and acetyl-CoA. By carefully adjusting factors like light intensity, CO2 levels, and nutrient availability, the researchers achieved a substantial increase in citramalate production.

Can be used to create other materials apart from plastics

Initially, the researchers produced only small amounts of citramalate. Later, they employed a systematic “design of experiment” approach to investigate how different factors interact.

This increased citramalate production. “As a result, they increased citramalate production to 6.35 grams per litre (g/L) in 2-litre photobioreactors, with a productivity rate of 1.59 g/L/day,” the researchers revealed in the press release.

The technique could also be used to create other eco-friendly materials. This is because pyruvate and acetyl-CoA are also used to create many other important biomolecules. Therefore, this method could be used in the production of materials for biofuels to pharmaceuticals.

The researchers highlight that this development contributes to global efforts to combat climate change and reduce our reliance on fossil fuels.

“By turning CO2 into something valuable, we’re not just reducing emissions—we’re creating a sustainable cycle where carbon becomes the building block for the products we use every day,” the author added.

They now aim to further fine-tune their techniques and investigate ways to increase production efficiently.

Furthermore, they are exploring how their optimization approach could be used for other metabolic pathways within cyanobacteria. This could help expand the range of sustainably produced bio-based products.

The findings were published in Biotechnology for Biofuels and Bioproducts.