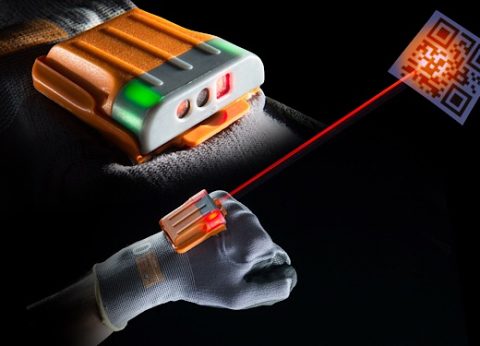

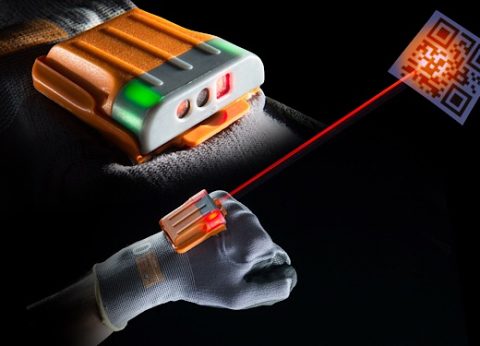

Use of Ultramid® Vision in a smart glove; ProGlove from Workaround makes scanning processes safer and more efficient; Optimized scanning capability and durability due to high light transmission and media resistance.

Use of Ultramid® Vision in a smart glove; ProGlove from Workaround makes scanning processes safer and more efficient; Optimized scanning capability and durability due to high light transmission and media resistance.

In close cooperation, Workaround GmbH, ALBIS PLASTIC GmbH and BASF have modified an important component of the smart glove ProGlove. After deep analysis, Ultramid Vision is now being used on the integrated scanning unit, allowing even simpler, quicker and safer work processes. The ProGlove is already in everyday use by leading branded manufacturers in the automotive, logistics and chemical sectors. The optimized version is now being presented to a wide specialist audience at Fakuma 2018 in Friedrichshafen, Germany.

Ultramid Vision allows light to pass through unhindered

The semitransparent polyamide, Ultramid Vision B3K, is used as a significant component of the glove. This semicrystalline polyamide allows light to pass through largely unhindered and impresses with its high transmission rate and low light scatter. After injection molding, metallic contacts are pressed into the polyamide and connected to the internal electronics. Due to the inherent toughness of Ultramid Vision, this process can be executed without risk of stress whitening or even failure. In addition, Ultramid Vision allows a clear view of the status LEDs in the display area. As a result, workers have both hands free and do not have to interrupt their work flow. “Last year, we brought Ultramid Vision to market, the world’s first partially crystalline polyamide for semitransparent to transparent components,” said Rainer Xalter, product developer in the Performance Materials division at BASF. “Thanks to its excellent media resistance and temperature stability as well as its good scratch resistance, this outstanding material is suitable for use in demanding environments.”

When used in factories and warehouses, where contact with aggressive fluids and hot surfaces can occur, the requirements for the housing material are particularly high. In such environments, the area of view for the laser scanner must work perfectly and must not be damaged by external influences. “The ProGlove smart glove is exposed to harsh conditions of use in industry,” explains Thomas Kirchner, CEO and founder of Workaround GmbH (ProGlove). “The part of the scanner which was previously manufactured from amorphous plastic didn’t always meet our requirements for this specific area of application.”

High media resistance offers a wide range of applications

“The requirements were appropriate resistance to chemicals and high translucence to ensure that workers can see the signals from the internally fitted LEDs”, explains Benjamin Schindler, who assisted with the project at ALBIS. “Polyamide proved to be suitable for this application right from the outset. Thanks to its outstanding properties, using the new Ultramid Vision was therefore an obvious choice.”

In addition to the uncolored base grade Ultramid Vision B3K UN, BASF is able to offer special product specifications. Depending on customer requirements, different levels of light diffusion and various colors can be adjusted. Ultramid Vision can be used especially for parts which require visual inspection. Whether in the automotive, construction or consumer goods industry or as a design element for bright color effects – Ultramid Vision leaves scope for a variety of design options.

************************

Why Should Be “A Paid-Subscriber” and “Advertiser”

Keeping an independent media in countries that impose limitations on self supporting media, will help to support the humankind’s freedom. If you believe it, please act to be a PRO-MEMBER by clicking “HERE“, or:

Please send your PR’s directly to my email address to be published in the world via ” http://pimi.ir ” my address is: aasaatnia@live.com

********

About ALBIS PLASTIC

ALBIS PLASTIC is one of the leading globally operating companies in the distribution and compounding of technical thermoplastics and thermoplastic elastomers. In addition to the product portfolio of well-known plastic manufacturers, ALBIS offers the plastic processing industry a diverse product range of high performance plastics, compound solutions and masterbatches. In 2017, the ALBIS Group, which has more than 1300 employees, achieved sales of 1.017 million euros. With 23 subsidiaries worldwide, the Hamburg based company is strongly represented in Europe with a growing presence in North Africa, the Asia Pacific and the Americas. At five German locations as well as in Knutsford (UK), Duncan, South Carolina (USA) and Changshu (China), ALBIS produces compounds and masterbatches, in part specializing in high-quality recycled compounds and green materials. All sites are certified according to the IATF 16949 or ISO 9001 standard.