The Coating of PE water pressure pipes is one of the most significant pipe market trends nowadays. The process is to cover the PE pipe with an additional PP layer via a coating process. This PP protection layer in the thickness of 0,8 mm to 3 mm allows the installation in the trench without sand. This reduces the cost for installation significantly.

The Coating of PE water pressure pipes is one of the most significant pipe market trends nowadays. The process is to cover the PE pipe with an additional PP layer via a coating process. This PP protection layer in the thickness of 0,8 mm to 3 mm allows the installation in the trench without sand. This reduces the cost for installation significantly.

The coating process compared to an extrusion process better, because the protection layer has to peel off before electrofusion- or butt- welding process. PP and PE cannot weld together and the grip or adhesive force is by shrinking of the PP to the PE pipe. Different process parameters can influence the grip. PE pipe temperature is the most influencing one.

Such a protection layer can consist of a multilayer structure with either barrier material or any other material combination.

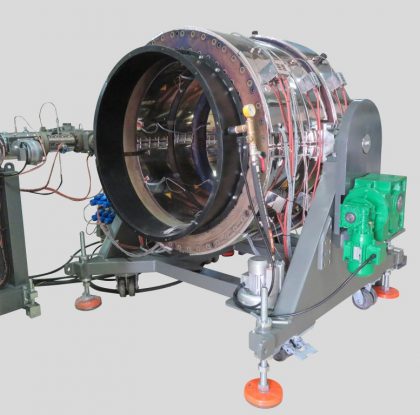

CONEXTRU GmbH specialised on extruders & pipeheads has finished the biggest crosshead in the product line of Conextru heads. The application is to coat PE 100 pipe with PP-HM protection layer in range of 1 mm to 3 mm.

Technical data Pipeheads

| Max. diameter | 1000 mm |

| Min. diameter | 400 mm |

| Max. throuput | 250 kg/h PP-HM |

| Distribution system | Helical spiral, 36 channels, special designed for low output – low volume |

| Die set system | Add on system – only 3 dies for full diameter range |

| Stripes | Eight colour stripes – only one unit for full range |

| Heating | inside heaters and outside heaters single phase total 130 kW |

| Vacuum | Vacuum control via PLC from extruder with speed adjustment of blower |

| Extrusion height | 1250 mm +/- 30 mm built up by side channel compressor |

| Trolley | strong design motorised tuning – + / – 90 degree from horizontal position |

| Flow channel | high glossy polished |

| Material | 42CRMO4 – surface nitride |

The whole coating equipment

| PO 1000 CR | range 400 – 1 000 mm, electrical box as interface box for all power cables and thermocouples. |

| Extruder C 45 30 | max. output 250 kg/h PE / 200 kg/h PP – barrier screw, ABB PLC control vacuum control for coating process, second control box for head heating, extruder position parallel to extrusion line, 90 degree adapter to head |

| Extruder C 30 25 | max. output 5 kg/h colour stripe material, height adjustable frame, short connection to colour stripe ring |