New highly reinforced polyamides in the Durethan P product series from LANXESS, has high dynamic durability; Improved mechanical properties and high potential for use in lightweight construction and mechanical engineering.

New highly reinforced polyamides in the Durethan P product series from LANXESS, has high dynamic durability; Improved mechanical properties and high potential for use in lightweight construction and mechanical engineering.

Substituting polyamide 66 while maintaining component weight

The mechanical properties of both high-modulus thermoplastics are at a high level similar to those of comparable polyamide 66 materials. “As a result, we also see both product innovations as cost-effective alternatives to polyamide 66 compounds, which have become significantly more expensive recently due to their limited availability,” explains Dr. Thomas Linder, an expert in the development of Durethan. Tests at LANXESS revealed that it is possible to use product variants with the same glass fiber content and therefore the same material density as substitutes. As a result the component weight does not increase.

At Fakuma, the international trade fair for plastics processing, in October 2018, LANXESS had presented the first representatives of the new product range with Durethan BKV30PH2.0, BKV35PH2.0, BKV40PH2.0, and Durethan BKV130P. Their glass fiber content levels are between 30 and 40 percent. Conceivable applications include air intake and oil filter modules for cars as well as load-bearing housings of power tools. The elastomer-modified Durethan BKV130P is particularly impact-resistant and is suitable for furniture locking system components, for example. All four compounds are also suitable substitutes for polyamide 66.

Better tensile strength at higher temperatures

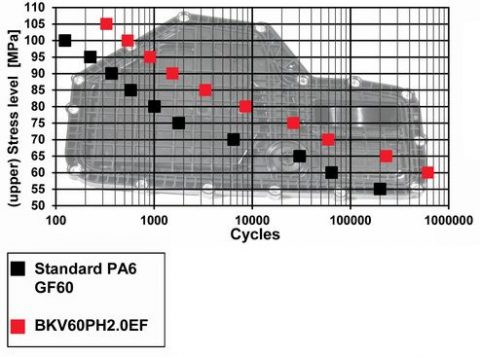

Like their “siblings”, the two new highly reinforced compounds are characterized by improved mechanical and structural properties. “For example, their tensile strength at high temperatures is higher than standard polyamide 6 variants with the same glass fiber content,” says Linder. To assess this behavior under a pulsating load, LANXESS has developed a HiAnt fatigue screening test that is based on a conventional Wöhler test. This revealed that under a transverse load of 65 megapascals, the lifespan of Durethan BKV50PH2.0 is around eight times longer than that of a standard polyamide 6 with the same glass fiber content. In a corresponding comparison, Durethan BKV60PH2.0EF demonstrates a fatigue behavior that is around ten times better.

At the same time, Durethan BKV60PH2.0EF is characterized by its good flow properties (easy flowing, EF). The thermoplastic is therefore easy to process despite its high degree of glass fiber reinforcement. Its flowability is of a similarly high level to that of a polyamide 6 with glass fiber content of 30 to 35 percent.

HiAnt – customer service right through to the start of production

The services with which LANXESS supports project partners during the development of components for use under pulsating loads include a wide range of component tests. “The equipment at our shaker technical center covers all current vibration tests for the fatigue behavior of components in vehicle applications,” explains Linder. Its customer service also includes pressure threshold tests on components from the vehicle cooling circuit as well as pressure change and backfire tests.

All these services are part of HiAnt. Under this brand, LANXESS has bundled its engineering expertise in the development of thermoplastic components for customers.

Forward-Looking Statements

This company release contains certain forward-looking statements, including assumptions, opinions, expectations and views of the company or cited from third party sources. Various known and unknown risks, uncertainties and other factors could cause the actual results, financial position, development or performance of LANXESS AG to differ materially from the estimations expressed or implied herein. LANXESS AG does not guarantee that the assumptions underlying such forward-looking statements are free from errors nor does it accept any responsibility for the future accuracy of the opinions expressed in this presentation or the actual occurrence of the forecast developments. No representation or warranty (expressed or implied) is made as to, and no reliance should be placed on, any information, estimates, targets and opinions, contained herein, and no liability whatsoever is accepted as to any errors, omissions or misstatements contained herein, and accordingly, no representative of LANXESS AG or any of its affiliated companies or any of such person’s officers, directors or employees accept any liability whatsoever arising directly or indirectly from the use of this document.

LANXESS is a leading specialty chemicals company with sales of EUR 7.2 billion in 2018. The company currently has about 15,400 employees in 33 countries and is represented at 60 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World and Europe) and FTSE4Good.