The following text which has been provided by University of Massachusetts Amherst, for the first time was originally published on Phys.org. Chosen for PIMI readers, it has been more informative by additional hyperlinks (shown in BOLD fonts) and extra images.

**************************************

In the quest to design the next generation of materials for modern devices—ones that are lightweight, flexible and excellent at dissipating heat—a team of researchers led by the University of Massachusetts Amherst made a discovery: imperfection has its upsides.

This research, published in Science Advances, experimentally and theoretically found that polymers (commonly referred to as plastics) made with thermally conductive fillers containing defects performed 160% better than those with perfect fillers. This counterintuitive finding challenges long-held assumptions that defects compromise material performance. Instead, it points to a promising new strategy for engineering polymer composites with ultrahigh thermal conductivity.

The study was led by UMass Amherst with collaborators from Massachusetts Institute of Technology, North Carolina State University, Stanford University, Oak Ridge National Laboratory, Argonne National Laboratory and Rice University.

Polymers have revolutionized modern devices with their unmatched lightness, electrical insulation, flexibility and ease of processing—qualities metals and ceramics simply can’t rival. Polymers are embedded in every corner of our tech landscape, from high-speed microchips and LEDs to smartphones and soft robotics.

However, common polymers are thermal insulators with low thermal conductivity, which can lead to overheating issues. Their inherent insulating properties trap heat, spawning dangerous hot spots that sap performance and accelerate wear, heightening the risk of catastrophic failures and even fires.

For years, scientists have attempted to enhance the thermal conductivity of polymers by incorporating highly thermally conductive fillers such as metals, ceramics or carbon-based materials. The logic is straightforward: blending in thermally conductive fillers should improve overall performance.

However, in practice, it is not this simple. Consider a polymer blended with diamonds.

Given a diamond’s exceptional thermal conductivity of about 2,000 watts per meter per kelvin (W m-1 K-1), a polymer that is composed of 40% diamond filler might theoretically achieve conductivity of around 800 W m-1 K-1. Yet, practical results have fallen short due to challenges like filler clumping, defects, high contact resistance between polymers and fillers, and low thermal conductivity of polymer matrices, which undermine heat transfer.

Given a diamond’s exceptional thermal conductivity of about 2,000 watts per meter per kelvin (W m-1 K-1), a polymer that is composed of 40% diamond filler might theoretically achieve conductivity of around 800 W m-1 K-1. Yet, practical results have fallen short due to challenges like filler clumping, defects, high contact resistance between polymers and fillers, and low thermal conductivity of polymer matrices, which undermine heat transfer.

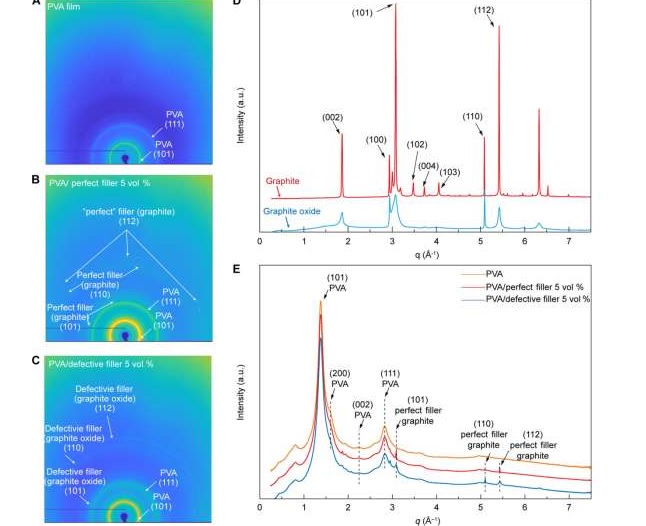

For their study, aimed at laying the foundation for understanding thermal transport in polymeric materials and controlling heat transfer across heterogeneous interfaces, the team created two polymer composites of polyvinyl alcohol (PVA)—one incorporating perfect graphite fillers and the other using defective graphite oxide fillers, each at a low 5% volume fraction.

As expected, the perfect fillers on their own were more thermally conductive than imperfect ones.

“We measured perfect fillers (graphite) on their own have high thermal conductivity of roughly 292.55 W m-1 K-1 compared to only 66.29 W m-1 K-1 for defective ones (graphite oxide) on their own—a nearly fivefold difference,” says Yijie Zhou, the lead author and a mechanical engineering graduate student at UMass Amherst.

However, surprisingly, when these fillers are added into polymers, polymers made with graphite oxide fillers containing defects performed 160% better than those with perfect graphite fillers.

The team used a combination of experiments and models—thermal transport measurements, neutron scattering, quantum mechanical modeling, and molecular dynamics simulations—to study how defects influence thermal transport in polymer composites.

They found that defective fillers facilitate more efficient heat transfer because their uneven surfaces don’t allow the polymer chains to pack together as tightly as the perfectly smooth fillers do. This unexpected effect, known as enhanced vibrational couplings between the polymers and defective fillers at the polymer/filler interfaces, boosts thermal conductivity and reduces resistance, making the material more efficient at transferring heat.

“Defects, at times, act as bridges, enhancing the coupling across the interface and enabling better heat flow,” says Jun Liu, associate professor in the Department of Mechanical and Aerospace Engineering at North Carolina State University. “Indeed, imperfection can sometimes lead to better outcomes.”

Xu believes these results, both experimental and theoretical, lay the groundwork for engineering new polymeric materials with ultra-high thermal conductivity. These advancements present new opportunities for devices—from high-performance microchips to next-generation soft robotics—to operate cooler and more efficiently through improved heat dissipation.

More information: Yijie Zhou et al, Defects vibrations engineering for enhancing interfacial thermal transport in polymer composites, Science Advances (2025). DOI: 10.1126/sciadv.adp6516