Simulating precision – avoiding errors By: New Ultrasim® module recognizes undesired thermal deformations at an early stage; Temperature simulations from -40 to 150°C taking account of the anisotropic fiber orientation in injection-molded plastic component: Exact predictions save development cycles.

Simulating precision – avoiding errors By: New Ultrasim® module recognizes undesired thermal deformations at an early stage; Temperature simulations from -40 to 150°C taking account of the anisotropic fiber orientation in injection-molded plastic component: Exact predictions save development cycles.

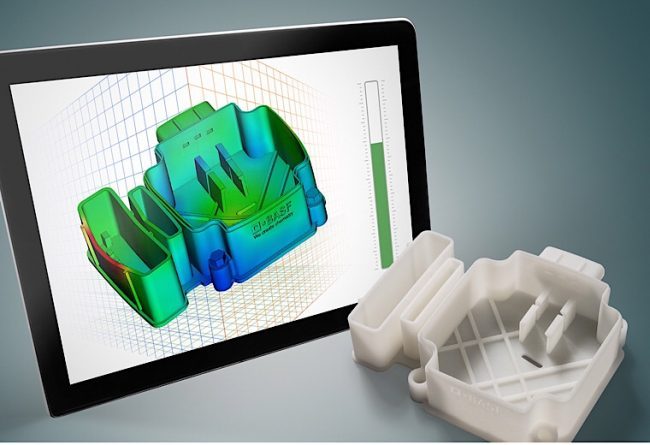

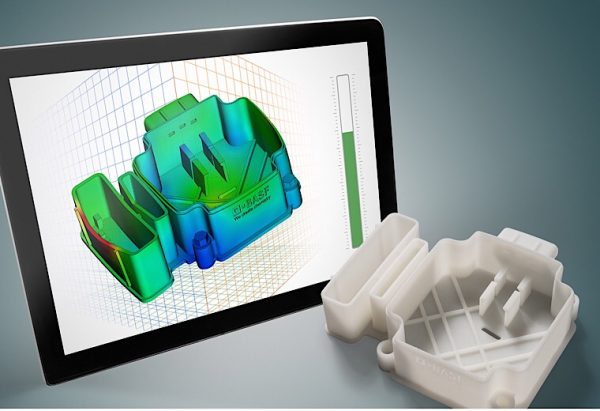

BASF now offers a new module for simulating applications of injection-molded components. BASF’s Ultrasim® simulation tool has long been able to deliver precise calculations of the anisotropic mechanical behavior of fiber-filled plastics after manufacturing in the injection-molding process. But another service has now been added: a thermomechanical model for fiber-reinforced thermoplastics now enables precise forecasts of temperature-dependent deformation via simulations.

One major benefit for customers is that they can now identify possible weak points virtually during the actual development phase for components and prevent them before the start of the series production phase. The new module considers the complex thermomechanical material behavior, the impact of the anisotropic fiber orientation as well as temperature distributions and changes in the component.

“During the early development phase, it is absolutely essential to make detailed forecasts for the end product,” says Andreas Wonisch, simulation expert at BASF. “Particularly with high-performance plastics that are used in cars and are exposed to huge temperature differences, possible deformations need to be predicted.”

Fiber-filled plastics display very complex thermodynamic behavior. Under a thermal load, there may be undesired deformations which depend on the local temperature and fiber orientation in the component. This is especially critical for E&E components with integrated switching elements. The highly sensitive electronics must not sustain any damage. Exact prediction of the thermal deformation with prior simulation using Ultrasim® thus saves time and money in the development process.

Integrative approach to simulation with Ultrasim®

With eaxtensive measurements directly on the material and on injection-molded test specimens, Ultrasim® offers comprehensive material characterization across the full temperature range. Instead of simulating at one single temperature it is possible to recalculate the typical temperature load from -40 to 150°C for various applications. The influence of the fiber orientation in the component, which results in anisotropic thermomechanical behavior, is considered through integration of the process simulation.

This allows for a much more comprehensive simulation, taking account of the rheological and thermal properties and the fiber orientation from the injection-molding process. The consequence is that component faults are identified and avoided at an early stage. BASF already uses the calculation model for a large number of applications, primarily for the automotive industry.

Automotive manufacturers benefit from precise simulations

The issue of electric mobility presents great challenges for the automotive sector. New and innovative components that need to protect highly sensitive conductor tracks, sensors or circuit boards are being developed. With severe temperature differences, no deformations to the components and thus damage to the electronics should occur. The new Ultrasim® module has already been successful with different parameters in various customer projects, for example a control electronics system. The simulation of thermal expansion for housings of electronic control units (ECUs) displayed very good conformity across the whole temperature range that was investigated. Other possible uses of the simulation tool would be for plastic components in headlights in which extensive power electronics are used and heat dissipation has an effect.

Read More from the “SOURCE’