Asahi Kasei Introduces Newly Developed Lightweight Material for Increased Efficiency and Safety of Electric Vehicle Batteries. The materials is SunForce™ m-PPE Particle Foam

Asahi Kasei Introduces Newly Developed Lightweight Material for Increased Efficiency and Safety of Electric Vehicle Batteries. The materials is SunForce™ m-PPE Particle Foam

Lithium-ion batteries constitute an essential component of the electrification of the transport sector. Optimizing weight, size, safety and efficiency of the batteries is crucial to accelerate electromobility. With the m-PPE (modified polyphenylene ether) particle foam SunForce™, the Japanese technology company Asahi Kasei developed a material providing solutions for these challenges.

As they show their full performance only at a stable temperature, both heating and cooling units are installed to the automotive battery pack, especially for PHEVs (plug-in hybrid electric vehicles) and BEVs (battery electric vehicle). However, creating the right temperature environment for the battery consumes a significant amount of energy, which is why an optimized thermal management of battery packs will become increasingly important. At the same time, safety issues such as fire protection and crash behavior are at the top of the OEMs’ agenda.

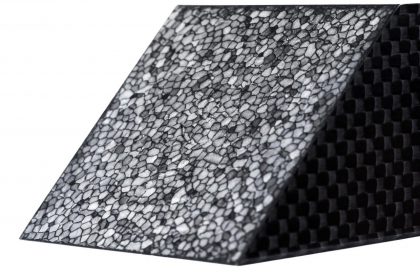

Asahi Kasei has developed SunForce™ – a particle foam based on the engineering plastic m-PPE – as a solution to these challenges. Compared to standard foams made of polystyrene or polyolefin, the use of m-PPE equips this foamed material with unique properties, opening new doors for applications in thermal management and fire protection. The material is certified with UL 94 V-0 (Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances) fire protection class by the “Underwriters Laboratories” safety certification organization and thus contributes to an overall product safety.

SunForce™ is the first-of-its-kind material certified with the UL94 V-0 standard. In addition to this outstanding flame retardancy, the particle foam provides superior heat insulation properties while at the same time functioning as a lightweight shock-absorbing material for automotive battery packs. The aforementioned properties and features allow functions and applications fields beyond those of conventional foams. The product is suitable for applications in automotive battery packs, lightweight shock absorbers, sandwich composite cores with carbon fiber, as well as for thermal insulation applications.

High Processability and Significant Cost Advantages

In addition to its broad range of properties, SunForce™ also provides significant advantages from a cost perspective: The material can be processed via steam molding, a manufacturing process that requires significantly less pressure compared to injection molding with a metal mold. The beads are filled into a mold and are then expanded and simultaneously fused with the heat from steam. The steam molding process with lower pressure allows the use of an aluminium mold, which can be produced at 10 to 20 percent of the costs for a steel mold. Furthermore, a significant reduction of resin for the production process can be achieved.

A high dimensional accuracy of the material is a key factor for the proper function of the molded part. SunForce™ utilizes the characteristics of m-PPE plastic with its low coefficient of linear expansion in comparison with other plastics and the effects of temperature in the fabrication process are relatively small – allowing a very precise and accurate product design with complex structures. At the same time, the small size of the beads allows the molding of thin walls, while maintaining a high mechanical strength and stiffness.

Strategy for the European Market

Asahi Kasei Europe is strengthening its marketing and business development activities with a convincing portfolio of high-performance materials such as engineering plastics, synthetic rubbers, technical fibers and products for high-performance batteries: The European automotive industry is a clear and declared goal, and SunForce™ plays a key role here.

“Our intention is to strengthen the application development and technical marketing of SunForce™ in Germany and Europe – not only for automotive battery parts, but also in automotive electronics and composite core applications for exterior and interior parts, as well as medical devices, electric products and other advanced technologies”, Nobuhiro Kikuchi, Manager for SunForce™ at Asahi Kasei Europe, explains the company’s ambitions on the European market.

SunForce™ was introduced to the Japanese market in 2011. Marketing activities on the European market have started in 2016, with the establishment of Asahi Kasei’s European operational headquarter Asahi Kasei Europe in Düsseldorf, Germany. Together with its recently introduced polyamide beads foam, the company will present SunForce™ at the Foam Expo Europe (10-12 September) in Stuttgart, and at the K 2019 (16-23 October) in Düsseldorf.

For more information on SunForce™, please visit here.