Aachen, September 23rd, 2019 – During K 2019, October 16th – 23rd, 2019, SIGMA Engineering GmbH from Aachen, Germany, will give an outlook on first developments for extrusion simulation with SIGMASOFT® Virtual Molding. In hall 13 at booth B31 SIGMA gives an insight to first developmental applications for the optimization of extrusion dies.

The behavior of the melt inside an extrusion die is comparable to the flow behavior inside the hot runner of thermoplastic or inside the cold runner of elastomer applications. For the extrusion die the temperature distribution inside the die alloy as well as the geometry of the flow channel also have significant influence on the flow behavior. With countless projects for thermoplastic and elastomer applications during the last years, SIGMA can rely on broad experience in the thermal and geometrical balancing of hot and cold runner systems. Thus, it is the logical next step for SIGMA to become active in the extrusion market.

Simulation helps to identify dead spots, excessively long dwelling times in the die or high pressure losses even before the die is built. In this way, tool changing costs and excessive trial-and-error runs to find the optimum configuration are reduced. The development of a new extrusion line gets faster, cheaper and more predictable.

First test series show that especially with SIGMASOFT® Autonomous Optimization flow channels of the extrusion die are automatically optimized within hours. Thus, the quality of the extrudate is distinctly improved. To achieve this goal, geometrical degrees of freedom for the extrusion die’s flow channel are defined inside the software. SIGMASOFT® then autonomously determines the ideal geometry for a dimensionally stable extrudate.

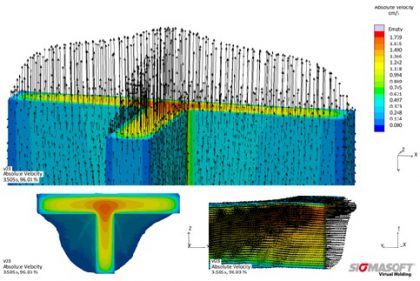

“The software currently available on the market helps to calculate the temperature distribution inside the extrusion dies. However, with the help of our software and the included Virtual DoE users will be able to automatically optimize their extrusion die finding a geometry which allows for an extrusion with homogenous velocities”, explains Timo Gebauer, CTO at SIGMA. With the optimized velocity profile inside the extrusion die the deformation of the extruded profile will be minimized.

Visitors interested in optimizing their extrusion processes are welcome to visit SIGMA in hall 13 at booth 13B31 to learn more about the current developments and how to utilize SIGMASOFT® to find the optimum configuration of the extrusion die.

The temperature distribution inside the extrusion die as well as the geometry of the flow channel are driving factors for the performance of an extrusion die and the dimensional stability of the extrudate. Assured by its broad experience in the thermal and geometrical optimization of hot and cold runner systems, SIGMA Engineering is making first steps into extrusion simulation. At K 2019 visitors of the SIGMA booth (hall 13, B31) will receive a first insight into current developments.

Figure 1 – Inhomogenous velocity distribution on the melt which leads to a deformation of the extrudate

The temperature distribution inside the extrusion die as well as the geometry of the flow channel are driving factors for the performance of an extrusion die and the dimensional stability of the extrudate.

The last article about Virtual Moulding published at this Channel was: Improving Part Deformation and Cycle Time with Virtual Molding