During the KPreview session, Stephane Peysson of Huntsman spoke about Elastomers Innovation – Premium PU & TPU. Passionate preople. Powerful possibilities. New urethanes product platform unveiled at K preview ahead of main launch at K 2019

During the KPreview session, Stephane Peysson of Huntsman spoke about Elastomers Innovation – Premium PU & TPU. Passionate preople. Powerful possibilities. New urethanes product platform unveiled at K preview ahead of main launch at K 2019

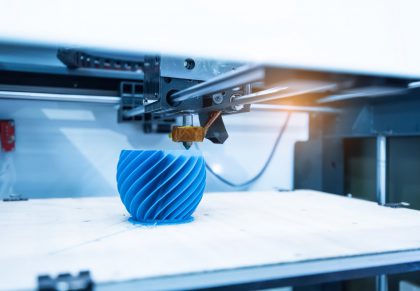

Everberg, Belgium – Global chemical company Huntsman today outlined details of a new range of additive manufacturing materials that it has developed, which are set to address emerging needs in the 3D printing industry. Huntsman’s IROPRINT® additive manufacturing platform contains three different kinds of urethane-based materials (resins, powders and filaments), which can be 3D printed using a variety of additive manufacturing methods including stereolithography (SLA), high speed sintering (HSS) and fused filament fabrication (FFF).

Initially, Huntsman is launching its range of soft, flexible IROPRINT® additive manufacturing materials in the global footwear and sports industry, where 3D printing is being used to make both customized and mass manufactured shoes. Longer-term, Huntsman plans to roll its IROPRINT® additive manufacturing platform out across a much wider range of applications and industries.

At present, the IROPRINT® additive manufacturing platform includes three product lines, which have been optimized to work with the main 3D printing techniques preferred by footwear producers.

• IROPRINT® R resins are a range of soft, durable, one-component liquid resin systems that can be 3D printed using SLA, digital light processing (DLP) and other radiation-curing methods.

• For companies looking to 3D print with powder-based materials, IROPRINT® P powders are a line of high performance thermoplastic polyurethanes (TPU) for HSS forms of printing.

• IROPRINT® F filaments are a collection of high performance TPU materials, which have a consistent diameter, and are designed for use with fused filament fabrication (FFF) and other extrusion-based printing techniques.

All three IROPRINT® additive manufacturing product lines have been optimized for the production of footwear components and are easy to use and print, offering advanced abrasion resistance, elongation and tear strength. For radiation-cured forms of printing such as SLA or DLP, IROPRINT® R resins also offer a long pot life and quick cure capabilities.

Speaking at the K preview on Wednesday 3 July, where Huntsman unveiled its IROPRINT® additive manufacturing platform, Stephane Peysson, Global Business Development Manager at Huntsman Polyurethanes, said: “Our innovation incubation team worked in close cooperation with end-users and industry leaders to develop our IROPRINT® additive manufacturing product portfolio. Together, we looked closely at what makes a good 3D printing material, and what’s been Stephane PeyssonDelivering Elastomers Innovation – Premium PU & TPU. Passionate preople. Powerful possibilities.