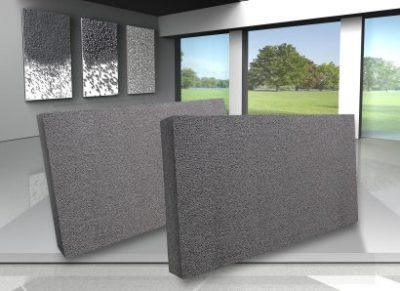

BASF is now offering its graphitic expandable polystyrene (EPS) granulate Neopor® in a biomass-balance version, Neopor® BMB. In accordance with the balancing method certified by REDcert, 100% of fossil raw materials are replaced by renewable raw materials – bio naphtha or biogas. Thus, the carbon footprint of Neopor® BMB improves by 90% compared to conventionally produced Neopor®.

Detailed information on the environmental impacts of an insulation board made of Neopor® BMB can be found in an environmental product declaration (EPD) drawn up by the German association of building product manufacturers, Institut Bauen und Umwelt e.V. (IBU), specifically for insulation materials made of Neopor® BMB.

First construction project using climate-friendly insulation boards made of Neopor® BMB

Under the trade name “Reverso”, Italian company L’Isolante is the first customer to manufacture insulation boards made of Neopor® BMB. Working with external thermal insulation composite system (ETICS) manufacturer IVAS and building cooperative AbitCoop, the insulation material producer installed Reverso in two five-story apartment buildings in Castenaso, Northern Italy. Containing 15 flats each, the two new buildings required approximately 3,000 m² of insulation board made of Neopor® BMB for their facade insulation (ETICS). The use of renewable resources in the production of Neopor® BMB avoids around 12 tons of CO2 emissions in comparison with conventional Neopor®. The central saving results from the lower heating energy consumption during its long use phase as an insulation board on the facade. “The interests of the future occupants of the buildings were not limited to the very high level of energy efficiency of the houses. They also wanted the environmental impact of the materials used in construction to be kept to a minimum. After a series of technical audits and tests, we were won over. Not just by the excellent product properties but also by the philosophy behind Neopor® BMB and Reverso,” says Andrea Prampolini, architect at AbitCoop.

Thanks to their optimally coordinated energy-efficiency measures, the buildings achieve Italy’s highest energy efficiency class, A4. This confirms an audit by the KlimaHaus agency based in Bolzano, Italy.

BMB products expand BASF’s styrenic plastic range

“Reducing CO2 emissions is one of the priorities of the current climate policy. Insulation materials made of Neopor® – even in its conventional form – already make a large contribution to sustainable building thanks to their efficient production method and long lifespan on a thermally insulated facade. We are therefore particularly pleased that the biomass balance method is enabling us to further improve the carbon footprint of an insulated building. In this way, we are making an active contribution to conserve fossil resources and to reduce the greenhouse gases generated by heating and cooling buildings,” explains Klaus Ries, head of Global Business Management Styrenic Foams at BASF. In addition to Neopor® BMB, BASF also supplies further packaging and insulation raw materials from its styrenic plastic range as biomass-certified products. These include Styropor® BMB and the green prefabricated insulation boards Styrodur® BMB.

EPDs: the Environmental Product Declarations

In cooperation with the company Bachl, a German manufacturer of insulation material, BASF has issued the EPDs for insulation boards made from conventional Neopor® and Neopor® BMB. When comparing 1 m³ of insulation board, it is evident that the global warming potentials (GWP) of the insulation material made of Neopor® BMB is improved by up to 66 percent, at the beginning of the life cycle (A1-A3). Considered over the entire life cycle, the carbon footprint is improved by 42 percent. The additional CO2 savings during the long usage phase as insulation board are not considered.

The environmental product declarations drawn up by the IBU provide an important basis for assessing the sustainability of buildings. An EPD describes building materials, building products, or building components in terms of their environmental impact on the basis of life cycle assessments as well as functional and technical properties. This quantitative objective, and verified information applies to the entire life cycle of the building product.