Making every single device and equipment as light as possible in any transporting machine (bicycles, motorcycles, cars, trucks, tram cabins, buses, vessels, planes and so on) has been the main concept of all designers and manufacturers since 1982. In those days the Carbon footprint in global warming became very serious and so one the main concepts, came into force: Lighter Parts is equal to Less Fuel consumption.

Based on these findings many research groups focused on innovations that could be ended to lighter parts. The following abstract edited by “Prabhat Ranjan Mishra” speaks about new materials that are as light as foams but could be used for making plane’s parts.

Extra hyperlinks and images have been provided by pimi’s editorial-team

*********************************************

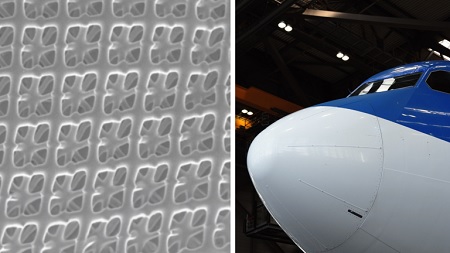

Researchers have developed high-performance nano-architected materials that have the strength of carbon steel but the lightness of Styrofoam. Developed by researchers at the University of Toronto’s Faculty of Applied Science & Engineering, the nanomaterials offer a unique combination of exceptional strength, light weight, and customizability.

Peter Serles, the first author of a recent study on the topic, maintains that nano-architected materials combine high-performance shapes, like making a bridge out of triangles, at nanoscale sizes. Nano-architected materials take advantage of the ‘smaller is stronger’ effect to achieve some of the highest strength-to-weight and stiffness-to-weight ratios of any material.

Perfect problem for machine learning to tackle

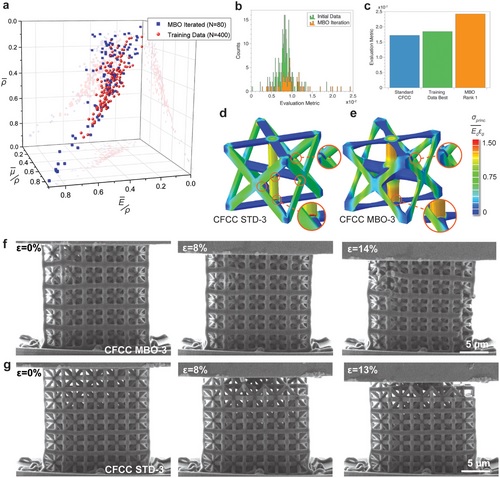

“However, the standard lattice shapes and geometries used tend to have sharp intersections and corners, which leads to the problem of stress concentrations. This results in early local failure and breakage of the materials, limiting their overall potential,” said Serles.

“As I thought about this challenge, I realized that it is a perfect problem for machine learning to tackle.”

Serles and Professor Tobin Filleter (MIE) worked with Professor Seunghwa Ryu and PhD student Jinwook Yeo at the Korea Advanced Institute of Science & Technology (KAIST) in Daejeon, South Korea, to design their improved materials. This partnership was initiated through UoT’s International Doctoral Clusters program.

Multi-objective Bayesian optimization ML algorithm

Researchers maintained that the KAIST team employed the multi-objective Bayesian optimization machine learning algorithm. This algorithm learned from simulated geometries to predict the best possible geometries for enhancing stress distribution and improving the strength-to-weight ratio of nano-architected designs.

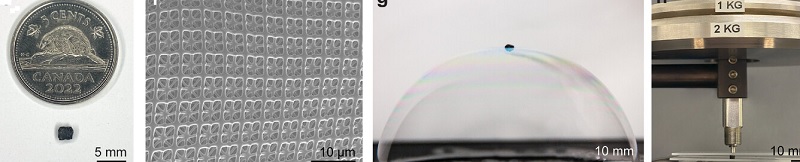

Nano-architected materials are made of tiny building blocks or repeating units measuring a few hundred nanometres in size — it would take more than 100 of them patterned in a row to reach the thickness of a human hair. These building blocks, which in this case are composed of carbon, are arranged in complex 3D structures called nanolattices, according to a press release by UoT.

Serles highlighted that this is the first time machine learning has been applied to optimize nano-architected materials, and researchers were shocked by the improvements.

Ultra-lightweight components in aerospace applications

“It didn’t just replicate successful geometries from the training data; it learned from what changes to the shapes worked and what didn’t, enabling it to predict entirely new lattice geometries,” explained Serles.

He stressed that machine learning is normally very data-intensive, and it’s difficult to generate a lot of data when using high-quality data from finite element analysis. But the multi-objective Bayesian optimization algorithm only needed 400 data points, whereas other algorithms might need 20,000 or more.

“So, we were able to work with a much smaller but an extremely high-quality data set,” said Serles.

It’s expected that these new material designs will eventually lead to ultra-lightweight components in aerospace applications, such as planes, helicopters, and spacecraft, that can reduce fuel demands during flight while maintaining safety and performance. Researchers believe that this can ultimately help reduce the high carbon footprint of flying.

“For example, if you were to replace components made of titanium on a plane with this material, you would be looking at fuel savings of 80 litres per year for every kilogram of material you replace,” added Serles.

Researchers will now focus on further improving the scale-up of these material designs to enable cost-effective macroscale components.

The research, published in the journal Advanced Materials, demonstrates the use of multi-focus multi-photon polymerization to create a millimeter-scale metamaterial comprising 18.75 million lattice cells with nanometer dimensions.