In 1985, the CEO of this news channel wrote an article about the use of sustainable drug delivery by advances in polymer materials. The article focusing on nitroglycerin delivery to heart patients was published at PIM magazine and absorbed a lot of attentions. Since then there has been a lot of advances in drug delivery via skin using the micro structure customizing of polymers. Now, an article is expressing the possibility of the drug delivery to melanoma patients. Part of the article is published here and the rest could be read from the link.

Melanoma is a deadly form of skin cancer that has been increasing in the U.S. for the past 30 years. Nearly 100,000 new cases of melanoma are diagnosed every year, and 20 Americans die every day from it, according to the American Academy of Dermatology. Now, researchers have developed a fast-acting skin patch that efficiently delivers medication to attack melanoma cells. The device, tested in mice and human skin samples, is an advance toward developing a vaccine to treat melanoma and has widespread applications for other vaccines.

The researchers will present their findings today at the American Chemical Society (ACS) Fall 2019 National Meeting and Exposition. ACS, the world’s largest scientific society, is holding the meeting here through Thursday. It features more than 9,500 presentations on a wide range of science topics.

“Our patch has a unique chemical coating and mode of action that allows it to be applied and removed from the skin in just a minute while still delivering a therapeutic dose of drugs,” says Yanpu He, a graduate student who helped develop the device. “Our patches elicit a robust antibody response in living mice and show promise in eliciting a strong immune response in human skin.”

Topical ointments can impart medications to the skin, but they can only penetrate a small distance through it. While syringes are an effective drug delivery mode, they can be painful. Syringes can also be inconvenient for patients, leading to noncompliance.

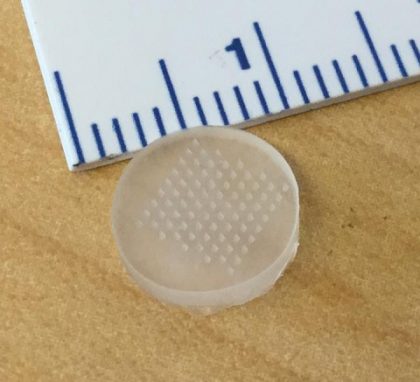

Microneedle patches, prepared with a layer-by-layer (LbL) coating method, are one easy, pain-free way to administer treatment. With the LbL process, researchers coat a surface with molecules of alternating positive and negative charge. For a robust drug film to form on the surface of the patch, every adjacent layer must be strongly attracted to each other and also to the microneedle. “But this attraction makes the entire film very ‘sticky,'” He notes. “Past methods, which have retained this ‘sticky’ nature, can take up to 90 minutes for a sufficient amount of drug to leave the patch and enter the skin.”

Paula T. Hammond, Ph.D., along with her graduate students He, Celestine Hong and other colleagues at the Massachusetts Institute of Technology (MIT), devised a way around this problem. They designed a new pH-responsive polymer with two parts. “The first part contains amine groups that are positively charged at the pH at which we make the microneedles, but that become neutral at the pH of skin,” He says. “The second part contains carboxylic acid groups with no charge when the microneedles are made, but which become negatively charged when the patch is applied to the skin, so there is an overall change in charge from positive to negative.” While sticky negative-positive-negative layers are still required for LbL film construction, the team’s patch quickly switches to repelling negative-negative-negative layers when placed on skin. After the microneedles pierce the skin and implant the LbL drug film beneath the skin, the drug leaves the patch quickly.

Read more from the “SOURCE”

The last article about medical subject publsihed at this channel was: The 9th Implantable & Internationale Medical Device M&T Conference