UK high-performance polymers producer Victrex (Thornton Cleveleys) is collaborating with Safran Cabin (Paris / France), a leading supplier of aircraft cabin interiors, to develop and qualify thermoplastic composite parts. The focus is on defining parts and moulds that can be adapted for multiple brackets, with the goal of achieving a family of designs compatible with the same mould.

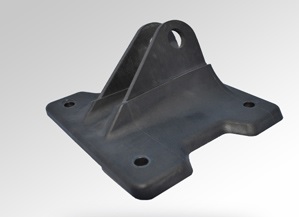

In a first project, the partners have created an aircraft cabin bracket where Victrexs AE 250 carbon fibre-polyaryletherketone (PAEK) composite is overmoulded with Victrex PEEK polymer. According to the UK polymers producer, stringent testing and qualification work have shown that structural aircraft parts made from AE 250 via hybrid overmoulding can withstand high levels of mechanical stress. Victrex added that the hybrid overmoulding technique is a scalable, repeatable technology that has the potential to help commercial aerospace customers face the challenges of needing much lower scrap rates, faster cycle times, part consolidation and a reduction in the number of secondary operations.

The initial prototype brackets were produced by Tri-Mack Plastics Manufacturing (Bristol, Rhode Island / USA). Compared to the original aluminium part, Victrex said the prototype illustrated 20% cost savings, 50% weight savings and a five times better buy-to-fly ratio the weight ratio between the raw material used for a component and the weight of the component itself.

The brackets are currently scheduled for final testing and qualification of production parts. They are expected to enter into service later in 2019.

Source: K-Portal

Image: The hybrid overmoulded cabin bracket for aircraft manufacturing is made of carbon fibre-PAEK composite and PEEK polymer (Photo: Victrex)