Lithium batteries (LBs) have become increasingly important energy storage systems in our daily life. Electronic products, electric vehicles and large-scale energy storage closely related to human life put up an ever-growing demand for rechargeable batteries.

Based on a news that Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) published, lithium-ion batteries, which are currently widely used, perform not well in terms of energy density and safety. As for rechargeable magnesium (Mg) metal batteries developed later, the lack of Mg electrolyte capable of effectively plating/stripping Mg has been impeding its practical development.

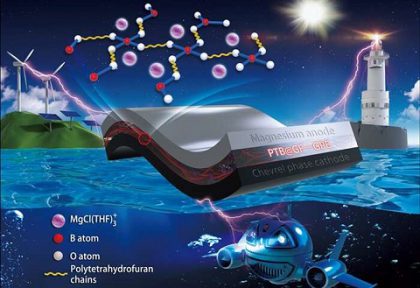

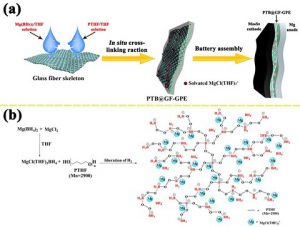

Recently, a research team led by Prof. CUI Guanglei from the Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences (CAS), exploited a novel rigid-flexible coupling gel polymer electrolyte (PTB@GF-GPE) coupling with significantly improved comprehensive performance. It was synthesized via in situ crosslinking reaction of magnesium borohydride and hydroxyl-terminated polytetrahydrofuran.

Over the past decades, although progress has been made in exploiting liquid Mg electrolytes capable of reversible Mg deposition, liquid electrolytes have been suffering the risks of being volatile and flammable.

Compared with liquid electrolytes, polymer electrolytes have the advantages of no internal short circuit and no electrolyte leakage as well as ease of fabrication and flexibility in structure.

This gel polymer electrolyte exhibits reversible Mg plating/stripping performance, high Mg-ion conductivity, and remarkable Mg-ion transfer number. The Mg batteries assembled with this gel polymer electrolyte not only work well at wide temperature range (-20 to 60 °C) but also display unprecedented improvements in safety issues without suffering from internal short-circuit failure even after a cutting test.

You can read more at the following source:

You can also fined more at the following link: