Just received from ENGEL Group, we have re-published the text. However, based on our policy we have added some extra hyperlinks (Shown in BOLD fonts) and images.

**********************************

The ENGEL Group, has provided the Rosenheim University of Applied Sciences with a state-of-the-art injection moulding cell. This system, comprising an ENGEL insert 500V/130 vertical injection moulding machine, an ENGEL infrared oven, and an ENGEL easix KR-10 articulated arm robot, is being used in the university’s teaching and research. There is a particular focus on the processing of thermoplastic, recyclable composites as well as the application of natural fibres.

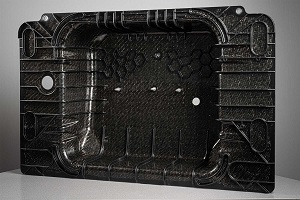

A key research focus at TH Rosenheim is on composite materials. Specifically, the project “Wood-Based Bioeconomy” deals with the production and processing of new materials from cellulose fibres and polypropylene (PP). The materials developed have properties similar to organosheets and can be processed accordingly. Particularly noteworthy is the upcyclingapproach of the project “ZIM – ReProHybrid“: materials from decommissioned car bumpers are shredded and processed into new organosheets. These can be back-injected in the injection moulding process with other, also recycled, materials from bumpers. These projects make a significant contribution to the sustainable use of resources and to the recycling of plastics.

“TH Rosenheim plays a significant role in research and development, especially in the development of sustainable injection moulding solutions and new materials,” says Dr.-Ing. Johannes Kilian, Head of Process and Application Technology at the ENGEL Group. “The collaboration is of great importance to us, as the university is not only known for its research strength in the field of plastics processing but also for its practice-oriented education. Our injection moulding cell allows for the integration of innovative technologies and digital solutions directly into teaching, as well as testing a wide range of applications for their recyclability.”

TH Rosenheim is actively engaged in research on sustainable materials, particularly in the area of natural fibres as reinforcement for thermoplastics. Prof. Dr.-Ing. Norbert Müller, Dean of Studies for the degree programs in Plastics Engineering and Sustainable Polymer Technology, emphasizes: “The new facility enables us to conduct practical investigations and further explore the use of sustainable materials in technical applications and in construction. Construction is significant for TH Rosenheim, as it recently acquired the right to award doctorates in ‘Advanced Building Technologies.’ According to Prof. Müller, this is a crucial sector where further research and development are needed for the recycling of materials, and where recyclable material systems based on natural fibre-reinforced plastics offer great potential for innovation. By using fibre reinforcements combined with a polymer matrix, parts can be manufactured through the injection moulding process that are highly strong while being lightweight. These properties are particularly advantageous for structural applications in construction, where stability coupled with light weight is required. The same applies to the production of complex shapes that often cannot be achieved with traditional building materials. This opens up new possibilities for innovative architectural designs.”

Furthermore, digitalisation plays a central role in the research at TH Rosenheim. By utilising ENGEL’s iQ process observer, the university gathers valuable data that, through semantic processing, allows for insights applicable to other uses. This represents a significant step towards machine learning and AI-supported applications in plastics processing. “Digital process monitoring opens up new possibilities for making production processes more efficient and sustainable,” explains Prof. Dr.-Ing. Norbert Müller. TH Rosenheim will continue to expand this area, as the combination of digital technologies with practical projects offers tremendous potential.

Furthermore, digitalisation plays a central role in the research at TH Rosenheim. By utilising ENGEL’s iQ process observer, the university gathers valuable data that, through semantic processing, allows for insights applicable to other uses. This represents a significant step towards machine learning and AI-supported applications in plastics processing. “Digital process monitoring opens up new possibilities for making production processes more efficient and sustainable,” explains Prof. Dr.-Ing. Norbert Müller. TH Rosenheim will continue to expand this area, as the combination of digital technologies with practical projects offers tremendous potential.

In addition to supporting teaching and third-party funded research, the ENGEL production cell is also used for direct R&D collaborations. Companies and institutions collaborating with TH Rosenheim can test technologies and trial new applications using this equipment.

With this partnership, ENGEL takes another step towards fostering the connection between research, education, and industry, and creating sustainable solutions for the future.