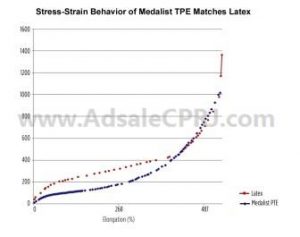

At MD&M West 2017, Teknor Apex will introduce a new family of medical-grade thermoplastic elastomers (TPE) for cast film provides the same elasticity, durability, and “feel” of latex without concerns regarding allergic reactions, odor, or residual curing agent.

The latex-free Medalist TPE film portfolio includes grades specifically designed for tourniquets and straps (Medalist MD-17340), therapy bands and sheeting (Medalist MD-10233 and MD-13240), and dental dams (Medalist MD-10308).

Like other Medalist medical elastomers, the new compounds are made with US Food & Drug Administration (FDA)-compliant ingredients, are compliant with ISO 10993-5 and REACH SVHC, are free of phthalates, and are produced in ISO13485 facilities in the US and – starting in January of 2017 – Singapore.

All are available worldwide as standard grades but Teknor Apex also provides custom formulations to meet specific requirement.

While closely resembling latex in performance, the new Medalist compounds eliminate concerns about latex allergy symptoms, which can range from skin irritation to more severe manifestations. Also unlike latex, the TPEs are odor-free, and their processing does not involve use of curing agents that can be present in trace amounts in finished products.

Teknor Apex said the new Medalist TPE also permits major cost savings over latex and other thermoset rubbers such as nitrile or neoprene due to a lower per-pound cost, elimination of the curing step, and the inherently greater processing efficiency of thermoplastics.

“Rubber extrusion is complicated, in terms of both equipment and production methods,” said Ross van Royen, Senior Market Manager of regulated products. “Because it is a lot easier and less expensive to set up a TPE extrusion process than one for rubber, companies may find it attractive to bring the manufacture of film products in-house rather than outsourcing it.”

MD&M West 2017 will be held from February 7-9 in Anaheim, the US.

Source : China Plastic & Rubber Journal