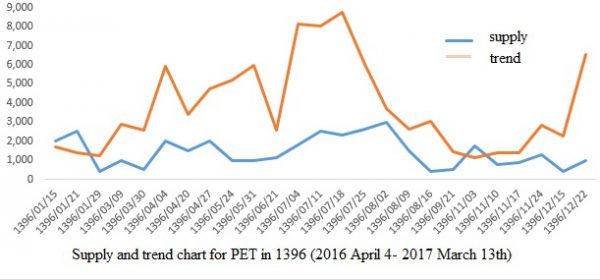

An expert on domestic petrochemical market has said that the reason for the higher demands of PET materials than the amount of supply is that consumption of this product as a main feedstock for products such as textiles and bottles is much more than what is every week supplied at the stock exchange.

An expert on domestic petrochemical market has said that the reason for the higher demands of PET materials than the amount of supply is that consumption of this product as a main feedstock for products such as textiles and bottles is much more than what is every week supplied at the stock exchange.

According to the PIMI reporters, Ethane gas is a strategic and beneficial feed of the petrochemical industry. The gas which is converted into Ethylene as the feed of many olefinic units of the country. PC units such as Jam, Aryasasol, Marun, Morvarid and Kavian are among the petrochemical units of the country that use Ethane. In the other hand, all of the country’s petrochemical plants that receive Ethane as a feedstock are ethylene producers and then products in the ethylene chain.

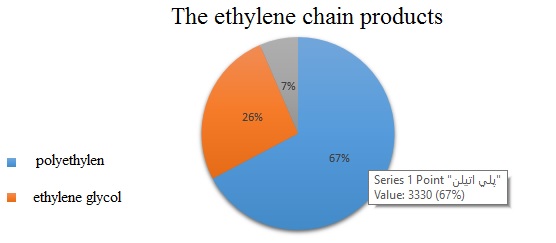

Important ethylene chain types include polyethylene, ethylene oxide, ethylene glycol, ethylene dichloride and then PVC. All these products are used in the production of many other polymer products, and so contribute to the added value and high employment to suport the country’s economy. For example, the end of the ethylene glycol value chain is PET textile grade, which is considered to be the primary and strategic material for the country’s textile industry. (Chart one shows the relative productions of PE and ethylene glycol)

In this respect, many countries, like China, South Korea and Turkey, have been able to import a high proportion of ethylene-based products, such as mono ethylene glycols, to keep their huge share of their textile market.

To consider what’s going on in Iran, respecting the PET related industries, Ahmad Hosseini, a petrochemical expert, has pointed that: In Iran a large amount of produced ethylene is devoted to the production of polyethylene, and so, the share of other products in the ethylene chain is not high. He said that: “During last year, from 4,950 thousand tons of ethylene produced in the country, 3,330 thousand tons of it converted to polyethylene, 1,300 thousand tons to ethylene glycol and 320,000 tons of it to PVC. However out of this amount, only 16% of the produced polyethylene (about 502,000 tons) was distributed for domestic converting units, and 2,431 thousand tons has been exported. In other words, only one petrochemical unit with a capacity of 500 thousand tons per year can be internalized. Also, from more than 1,300 thousands tons of produced ethylene glycol, about 1 million tons of it has been exported and only 300,000 tons has been consumed domestically.

He added that the most important converting chains of Ethane to ethylene chains are ethylene oxide and then ethylene glycols. Currently, the country’s three petrochemical companies, each with a capacity of 443, 500 and 400 thousand tons, are producers of these products of the Ethane chain. This petrochemical also said that: “One of the important uses of ethylene glycols is in the production of mono-ethylene glycols, which is used as a raw material for the production of polyester yarn, polyester chips and bottle production.” These products are very important in terms of creating added value and employment in downstream textile and bottle producing industries. Anti freezing products can also be mentioned as other products of the ethylene glycol chain.

PET production restriction. (Chart Two shows the supply and trend for PET in last Iranian calendar year)

Hosseini, referring to the fact that out of the country’s production of 1,300 thousand tons of ethylene glycol, only 30% is consumed domestically for PET production by “Tondgouyan PC unit” and the rest is exported in the form of ethylene glycol confirmed: “This negligence of the continuation of the ethylene glycol value chain could be seen in the existing plants and under construction projects like Boushehr and Pars PC units which with a capacity of 554 tons each) have concluded only with the production of ethylene glycol, and there is no products like PET in their products’ baskets.

He added: “Looking to the traded volumes on commodity petrochemicals at IME, we can see that due to low production of the textile grade of PET which is produced only by one PC unit, in most cases it is traded in a state of maximum competition”. This product is used as a feed in many major industries such as textiles. In fact, one of the reasons for the poor state of the textile industry in the country is due to the feed shortage of the textile grade of PET.

Hosseini continued: “In most weeks of PET trading on the stock exchange, the demand was several times of the supply. The reason for the high demand is high consumption of this product as a supplement to the industries like textiles and bottles.”

************************

Why Should Be “A Paid-Subscriber” and “Advertiser”

Keeping an independent media in countries that impose limitations on self supporting media, will help to support the humankind’s freedom. If you believe it, please act to be a PRO-MEMBER by clicking “HERE“, or:

Please send your PR’s directly to the email address of the Chief-Editor in order to be published at once in the world via ” http://pimi.ir ” The address is: aasaatnia@live.com.

Why Should Be “A Paid-Subscriber”?

Keeping an independent media in countries that impose limitations on self supporting media, will help to support the humankind’s freedom. If you believe it, please act to be a PRO-MEMBER by clicking “HERE“