Increased quality and efficiency in laser welding applications were the focus of development: With LPKF‘s latest software concept, users only need a few mouse clicks to convert a CAD layout into a laser-welded plastic component – with reliable, traceable results.

The LPKF software package offers a complete solution for laser plastic welding: from creating the weld contour to controlling and monitoring the welding system. Three process elements define the software concept of LPKF’s laser plastic welding systems. First, the automatic generation of the weld seam contours based on the CAD data, and the transfer to the machine; then the implementation via the machine control for the final welding process. And last but not least, the ability to achieve the same results worldwide with a single set of parameters on calibrated machines. The software guides the user quickly and easily through the entire workflow. All elements have a uniform Look & Feel, so that the user does not have to undergo any conversion during the implementation of his welding process.

Element 1: Software for process equipment (ProSeT 3D)

This software takes over the complex process setup from the operator. Using CAD data – from DXF or STP files – and material and surface data, the optimum welding contours are calculated. Setting up the process parameters and possible contour adjustments can be implemented with just a few mouse clicks. Even for complex components, contour generation is ready within in just a few minutes.

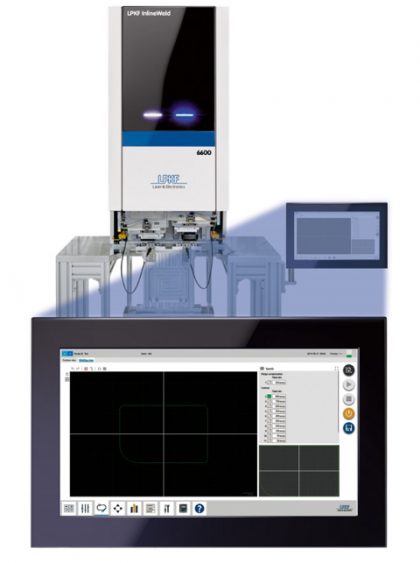

Element 2: Software for machine control (WeldPro)

Once the welding contour has been transferred to the welding system, the machine software (WeldPro) provides all the tools for contour and process management known from the ProSeT process setup software.

The touchscreen-based program combines all relevant modules such as process data recording and allows the user to fully control all aspects of the welding process.

The modular structure of the software offers the possibility to implement further features. For selected machines, for example, a camera function can further simplify the process setup in advance by comparing the contour live with the real position of the component.

Element 3: Calibrated machines for reliable results

Extensive calibration procedures ensure the comparability and transferability of welding processes between different machines. For example, the scan field calibration of the machines compensates for deviations that are possible, for example, due to external mechanical influences. In this way, with a single data set, the same results can be produced on all calibrated systems, which significantly reduces the setup and adjustment effort.

Conclusion

With the latest generation of ProSeT 3D and WeldPro software packages, LPKF is setting standards in the field of laser plastic welding.

The software which is available for all new LPKF welding systems enables contour generation and process optimization within just a few steps, thus contributing to improved added value. Upgrades for existing machines are also possible at a later date.

HOMEPAGE Image: The user-friendly software is installed in the LPKF InlineWeld 6600. It works with several simple icons and is basically intuitive.

About LPKF

LPKF Laser & Electronics AG manufactures machines and laser systems used in electronics fabrication, medical technology, the automotive sector, and the production of solar cells. Around 20 percent of the workforce is engaged in research and development.

The last article about “Laser Welding” published at PIMI News Channel was: Process-Safe Laser Welding of PPS Enabled By DIC And EVOSYS