DSM: PPA grades launched as alternative to die-cast metals / Cost savings of up to 50% offered / Die-cast replacement market growing close to 10% annually

The “ForTii MX grades extend DSM‘s portfolio of the high-performance polyphthalamides (PPA) based on polyamide 4T. They are said to show better properties than existing PPA materials in terms of mechanical strength and toughness across a broad range of temperatures. Grades are available with glass-fibre reinforcement ranging from 30% to 50%.

Ralf Ponicki, programme manager for die cast replacement, said injection mouldings in ForTii MX could offer cost savings of up to 50% compared to parts die-cast in aluminium, magnesium and zinc. High-performance thermoplastics already offer typical cost reductions of 20-30% over die-casting.

Improvements in weight savings are on a similar level. Extra possibilities exist for integrating functionality, improving product safety, and simplifying logistics and handling, Ponicki noted.

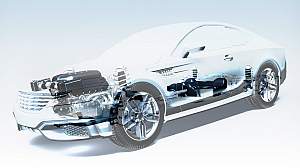

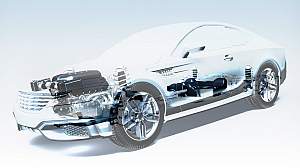

Potential is seen for the grades in structurally loaded parts such as housings, covers and brackets in the automotive powertrain, air and fuel systems, chassis and suspension, and also in industrial products, pumps, valves, actuators, home appliances and fasteners.

Plastics have gradually been replacing metals in various applications for many years but DSM believes the potential for replacing die-cast metal parts remains extremely large. It said the market for die-cast replacement is growing by nearly 10% per year and the increasing availability of materials such as ForTii MX would ensure that high growth continues and possibly increases well into the future.

As a result, the company is continuing to develop new series of ForTii for this particular market. “We still have at least one ace up our sleeve, commented Ponicki. DSM plans to make further announcements later this year.